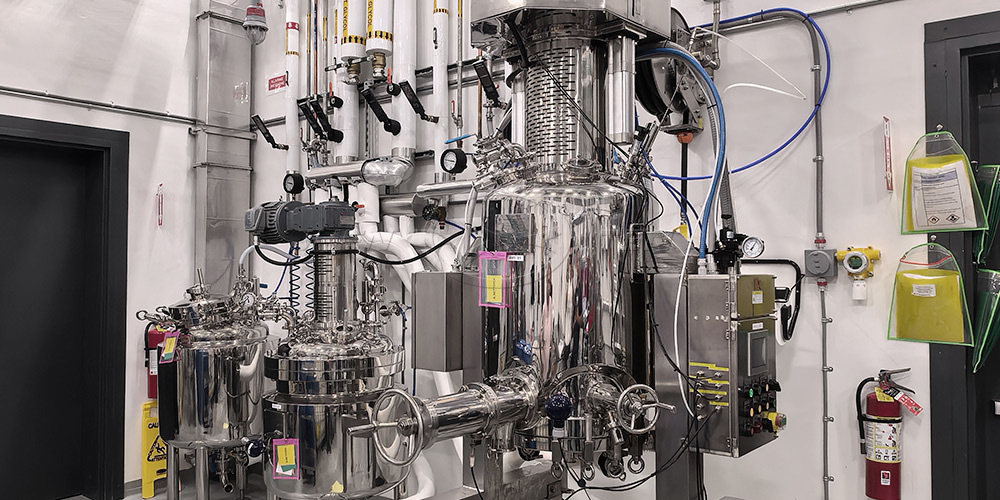

Reactors (50L–5000L) with double mechanical seals

Welcome to the 'Online Message' section! If you have any suggestions or questions about our products, please feel free to provide us with feedback through this section.

We will reply to you within 24 hours.